D971F Electric Fluorine-Lined Butterfly Valve Series

manufacturer: Kaiweixi Valve Group Co., Ltd

Eml: Carrie@kaiweixi.com

Tel: +86 (577) 67038872

Mob: +86 189 6779 6392(WeChat Same Account)

product drawing

D971F Electric Fluorine-Lined Butterfly Valve Series

Overview

The D971F Electric Fluorine-Lined Butterfly Valve is a corrosion-resistant valve that utilizes a high-performance fluorine-lining process (polytetrafluoroethylene). It is designed for precise on/off control or flow regulation of corrosive media in pipelines, achieved through 90-degree rotation of the disc driven by an electric actuator. The valve features a wafer or flanged connection design, with both the inner wall of the valve body and the surface of the disc completely lined with polytetrafluoroethylene (PTFE) or modified fluoropolymer, providing full flow path corrosion protection. Upon receiving control signals, the electric actuator transfers motor torque to the valve stem via a gear reduction mechanism, driving the disc to rotate precisely within the fluorine-lined seat. The fluorine lining offers exceptional chemical inertness, enabling the valve to withstand a wide range of highly corrosive media, including strong acids, alkalis, and organic solvents. The D971F Electric Fluorine-Lined Butterfly Valve is widely used in the control of corrosive media pipelines across industries such as chemical processing, pharmaceuticals, electroplating, and environmental protection.

Features

1、Full Flow Path Fluorine-Lining Anti-Corrosion: The inner cavity of the valve body and the surface of the butterfly disc are entirely lined with fluoroplastics such as polytetrafluoroethylene (PTFE), PFA, or FEP through overall molding or sintering processes, forming a complete corrosion-resistant barrier. This provides excellent chemical stability and resistance to most highly corrosive media.

2、Electric Intelligent Control: Equipped with an integrated or separated electric actuator, supporting 4–20 mA signal input or switch control. It enables remote automated operation, proportional regulation, and program control, making it suitable for automated production lines.

3、Zero-Leakage Sealing Design: The butterfly disc features a fluorine rubber coating or fully fluor-lined structure, forming an interference fit with the fluor-lined valve seat. This ensures superior sealing performance, achieving bidirectional zero leakage (sealing level up to Class VI) and effectively preventing medium leakage.

4、Lightweight and Compact Structure: Adopting wafer or flange connection, with short face-to-face dimensions and light weight, requiring minimal installation space and facilitating layout in densely packed pipelines. The electric actuator is compact in size, offering high overall integration.

5、Low Torque and Wear Resistance: The fluor-lining layer has a low friction coefficient, reducing the opening and closing resistance of the butterfly disc. The electric actuator is equipped with torque protection to prevent overload damage and extend valve service life.

6、Temperature and Pressure Adaptation: The fluor-lining layer can withstand temperatures ranging from -29°C to 180°C, with specially modified fluoroplastics capable of enduring higher temperatures. The valve design pressure can reach PN16, meeting various operational requirements.

7、Easy and Safe Maintenance: The simple structure allows for easy disassembly. The fluor-lining layer exhibits good anti-adhesion properties, preventing medium accumulation. The electric actuator features a high protection rating (typically IP67), making it suitable for humid and corrosive environments.

8、Optional Sanitary Configuration: Polished finishes and sterile design versions are available to meet cleanliness requirements in industries such as pharmaceuticals and food. Supports Clean-in-Place (CIP) and Sterilization-in-Place (SIP) processes.

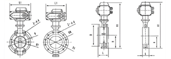

Dimensions & constructral diagram

D971F Electric Fluorine-Lined Butterfly Valve Series constructral diagram(pic1)

The main technical parameters

| Stem | Stainless Steel (304/316) |

| Packing | Flexible Graphite / PTFE Packing |

| Packing Gland | Ductile Iron |

| Electric Actuator Housing | Aluminum Alloy |

| Connecting Bolt | Stainless Steel (304) |

Standard

| Item | Specification | Unit |

|---|---|---|

| Nominal Pressure | 1.6 | PN |

| Strength Test Pressure | 2.4 | MPa |

| Seal Test Pressure | 1.76 | - |

| Operating Temperature Range | ≤80 | ℃ |

The main external and connection dimensions

| Nominal Diameter DN | L | KI | K | DI | Z-Φd | D | LI | |

|---|---|---|---|---|---|---|---|---|

| 50 | 43 | 452 | 80/112 | 120/125 | 4-18 | 165 | 208 | |

| 65 | 48 | 475 | 88/115 | 136/145 | 4-18 | 185 | 208 | |

| 80 | 46/49 | 516 | 98/120 | 160/ | 8-18 | 200 | 208 | |

| 100 | 52/56 | 551 | 115/140 | 185 | 8-18 | 220 | 208 | |

| 125 | 56/64 | 566 | 129/170 | 210 | 8-18 | 220 | 208 | |

| 150 | 56/70 | 606 | 140/180 | 240 | 8-22 | 280 | 256 | |

| 200 | 60/T6 | 731 | 175/210 | 295 | 8-22 | 345 | 256 | |

| 250 | 68/T6 | 778 | 202/240 | 355 | 12-22 | 395/409 | 256 | |

| 300 | 78/83 | 830 | 242/290 | 410 | 12-22 | 445/460 | 256 | |

| 350 | 78/92 | 996 | 266/320 | 470 | 16-22 | 505/520 | 346 | |

| 400 | 102 | 1058 | 298/350 | 515/525 | 16-26 | 565/580 | 346 | |